Unraveling the Tape: A Guide to Different Types of Tapes in the Packaging Industry

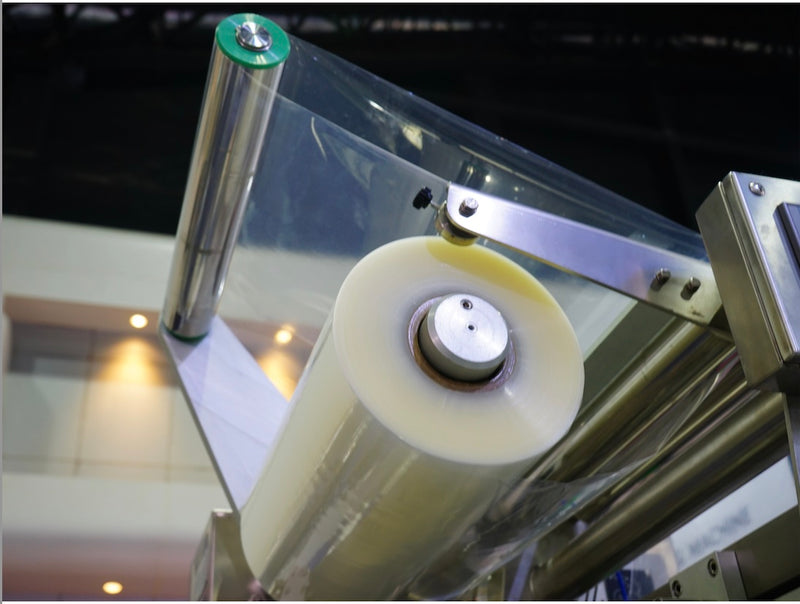

Polypropylene Tape: Let’s start with the most common one - the polypropylene tape. Known for its low cost and high tensile strength, polypropylene tapes are widely used for sealing cartons. They come in various thicknesses, and some options have added reinforcements for extra strength. The adhesive usually used is acrylic or hot-melt, which provides a strong bond to surfaces.

PVC Tape: PVC (Polyvinyl Chloride) tape, another popular choice, is known for its durability and resistance to moisture and chemicals. Its rubber-based adhesive ensures a sturdy bond even in varying temperatures, making it an excellent choice for shipments that will be exposed to extreme conditions.

Filament Tape: For those heavy-duty packages, filament tape is your go-to. Reinforced with fiberglass filaments, this tape is extraordinarily strong and resistant to tearing. It’s perfect for bundling items together, closing corrugated fiberboard boxes, and securing heavy or bulky items.

Gummed Paper Tape: Environmentally-conscious businesses will find gummed paper tape to be a favorite. Made from paper and a starch-based adhesive, this tape becomes a permanent part of the box, providing additional security. It’s recyclable, biodegradable, and can even be custom-printed with your brand’s logo for that extra touch.

Masking Tape: Though not primarily used for sealing packages, masking tape has its place in the packaging industry. With its easy-to-tear nature, it’s used for labeling, color-coding, or securing protective materials in place during the packaging process.

Foam Tape: When you need to cushion or create a seal against air or moisture, foam tape is the solution. Its unique structure provides insulation, cushioning, and gap-filling properties, making it ideal for securing delicate items.

Specialty Tapes: Besides the tapes mentioned above, there are specialty tapes designed for specific purposes. For example, anti-static tapes for electronic components, freezer tapes for cold storage, and tamper-evident tapes for security.

Selecting the right commercial tape is a critical step in ensuring the safe and efficient packaging of your products. From the versatile polypropylene tape to the environmentally-friendly gummed paper tape, the options are varied. Understanding the specific needs of your packaging and the unique properties of each tape type is key to making the right choice. Let Wolfpack Packaging be your partner in sourcing the highest quality tapes tailored to your requirements.

Contact us today for expert advice and access to a wide range of packaging solutions.